Message to readers: smoking sucks, f&&& smoking. It's killing people.

Case Study 1: How robots improve the efficiency of the packaging work

Scandinavian Tobacco Group is constantly optimizing its pipe tobacco production to ensure a healthy working environment and competitive production.

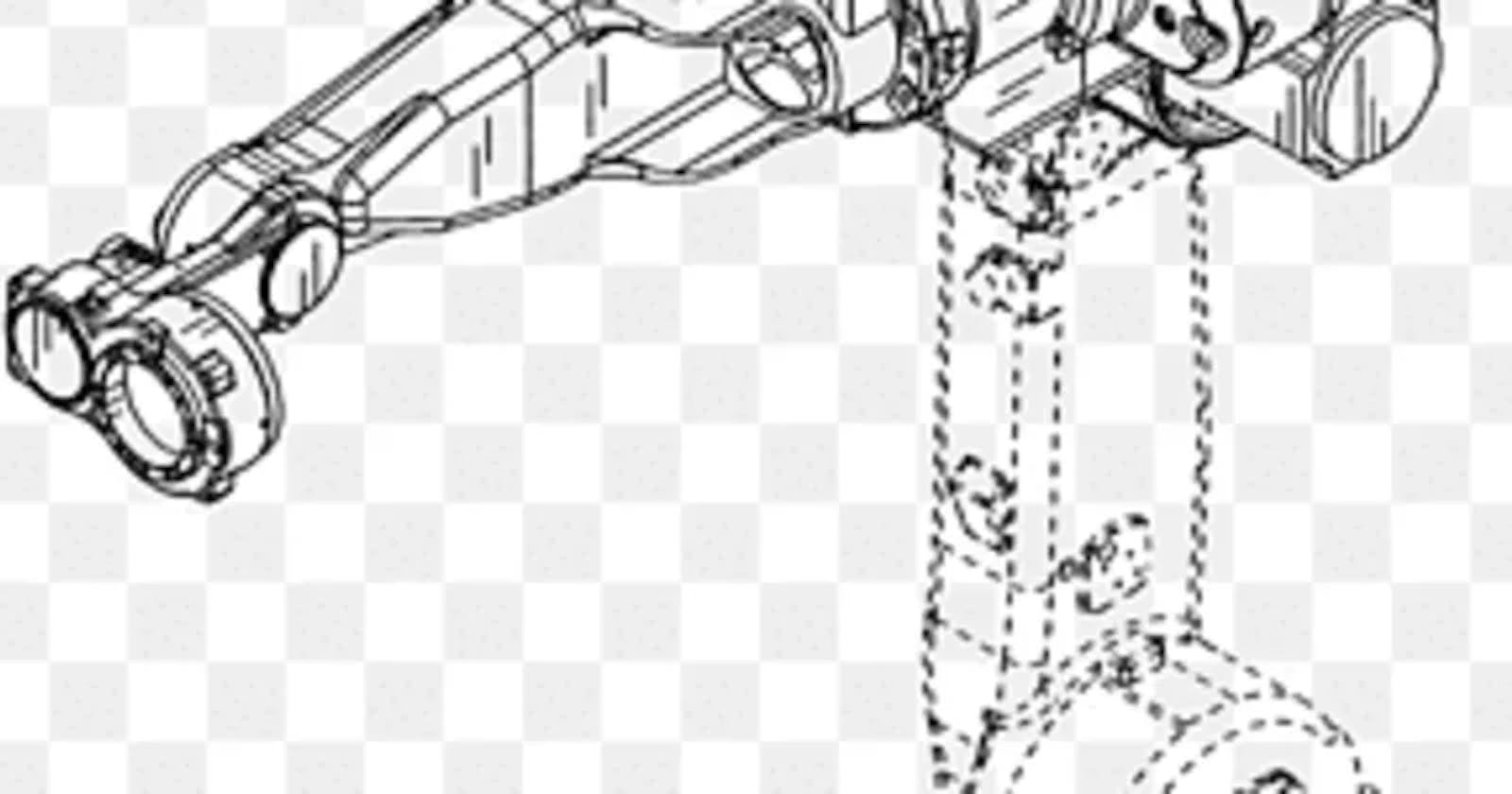

The giant of tobacco recently selected a robot from Universal Robots for a task that no other robot on the market is capable of performing.

The world's largest producer of tobacco for pipes uses Universal Robots technology for avoiding its employees having to repeatedly make strenuous movements with serious back fatigue. A robot took over the management of metal box lids of tobacco in a tobacco packaging installation.

youtube.com/watch?v=R6QIhttHLc8

{% youtube R6QIhttHLc8 %}

“This installation freed 1 or 2 people who previously did the job manually. Now they perform other duties in the factory, which means we don't have to spend as much on temporary workers, ” says Henning Kristensen, Scandinavian line manager Tobacco Group.

There was no room for protection of the robot in the factory installation.

“We ultimately chose Universal Robots because their robots are the only ones approved for operation without the need for protection. Thus the costs were reduced and the installation was very simplified, ” says Henning Kristensen.

The factory is located in Assens in Denmark.

“We have to make sure that the owners are convinced that producing tobacco here is still affordable.

For this reason, we are constantly striving to optimize our processes, ” says Henning Kristensen.

Having self-confidence is a good thing. As for the Scandinavian Tobacco Group, the factory must have resources installed to manage their machinery.

youtube.com/watch?v=ay_J-k1FnKY

{% youtube ay_J-k1FnKY %}

“Who has never had a breakdown right when the programmer just came out? For this reason, we want to keep the know-how inside the building, so that we can guarantee fast and avoid operating times of having to pay expensive external consultants.

One of our technicians programmed the Universal Robots robot himself and the gripping tools were also designed by our technicians” explains Henning Kristensen.

A little bit of history: Scandinavian Tobacco Group sells its products in over 100 countries and is the largest manufacturer of pipe tobacco world and the second-largest producer of cigars. Globally, the Group has divisions in more than 15 countries, with a total of about 10,000 employees. Production began in 1750 when the first factory of the Group started operations in Denmark.

youtube.com/watch?v=qJrcm_fTCPE

{% youtube qJrcm_fTCPE %}

But what about costs? Scandinavian Tobacco Group reported that the costs recovery period was 330 days. Holly Molly, right? The robot was a prudent investment for the manufacturer of tobacco because it leaves free workers for other duties.

Case study 2: The robot manipulates parts of microscopic size for Oticon company

< Rediscover the sounds of your life with Oticon hearing aids. < Explore all our hearing aids & accessories, learn about hearing loss, and more.

Hearing aids of today always are smaller, to the point that they are hardly noticeable when they are mounted in the ear of the person. This involves large requirements of precision at the production level. High technology team of Oticon now uses few Universal Robots robots for manipulating parts only a millimeter long.

youtube.com/watch?v=GAfWxc0hErQ {% youtube GAfWxc0hErQ %}

youtube.com/watch?v=JMlWwJ4Oxsc

{% youtube JMlWwJ4Oxsc %}

Oticon has used robot technology for the past decade, but the innovative trend towards nearly invisible hearing aids means parts that need to be built and assembled very small.

“The parts of modern appliances acoustics are often about a millimeter in size, so we need a solution that can extract very small parts from a mold. It is not possible to do it manually " declares Arne Oddershede, supervisor of the maintenance department of one of the Oticon manufacturing facilities.

youtube.com/watch?v=qJrcm_fTCPE

{% youtube qJrcm_fTCPE %}

The two large two- and three-axis robots that Oticon used in the past were no longer suitable. Movements that are limited to the inside / out and up / down are not effective enough.

“If there is a small part in one mold, for example, maybe needed to tilt it, ” says Lars Gasberg, Sales Director by Amiga, the system integration specialist who distributes Universal Robots products.

youtube.com/watch?v=qJrcm_fTCPE

{% youtube qJrcm_fTCPE %}

Wider range, shorter production cycles Another challenge faced by Oticon is that the company stands offering more and more variations and models, but in cycles production content, which of course they were made in the most economical way possible.

“We switched to Universal Robots because we have wanted a more flexible solution that is also financially viable for multiple productions small. Important is that the robot is easily accessible and logically designed, as well as be easy to reprogram. Traditional robots require specialized personnel, while with this robot all our technicians are simply able to take it and show him the model of movement",

Previous Articles